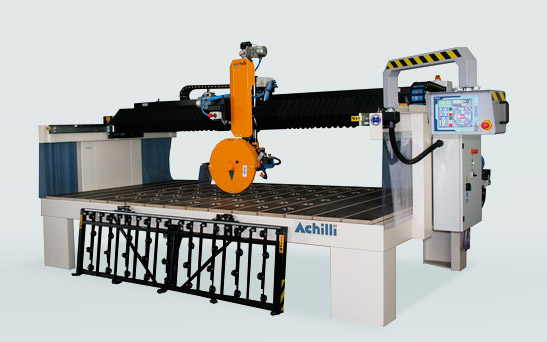

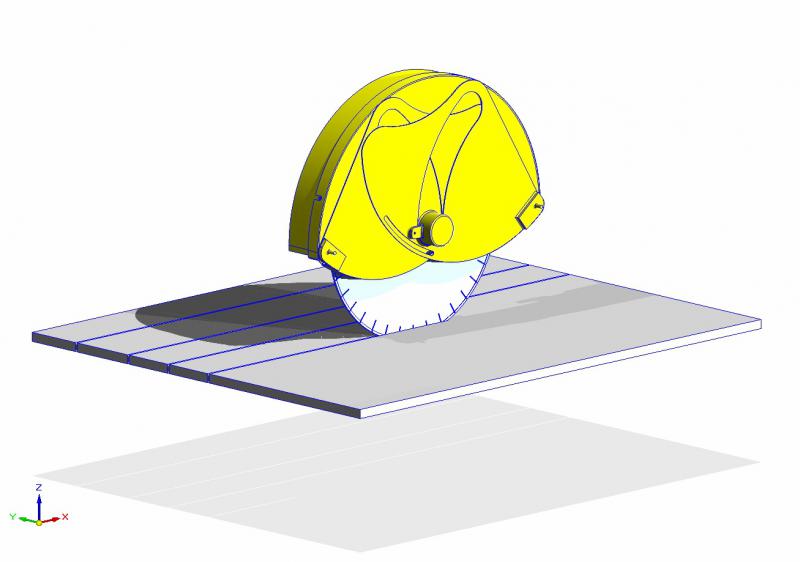

Monoblock bridge saw MBS TS

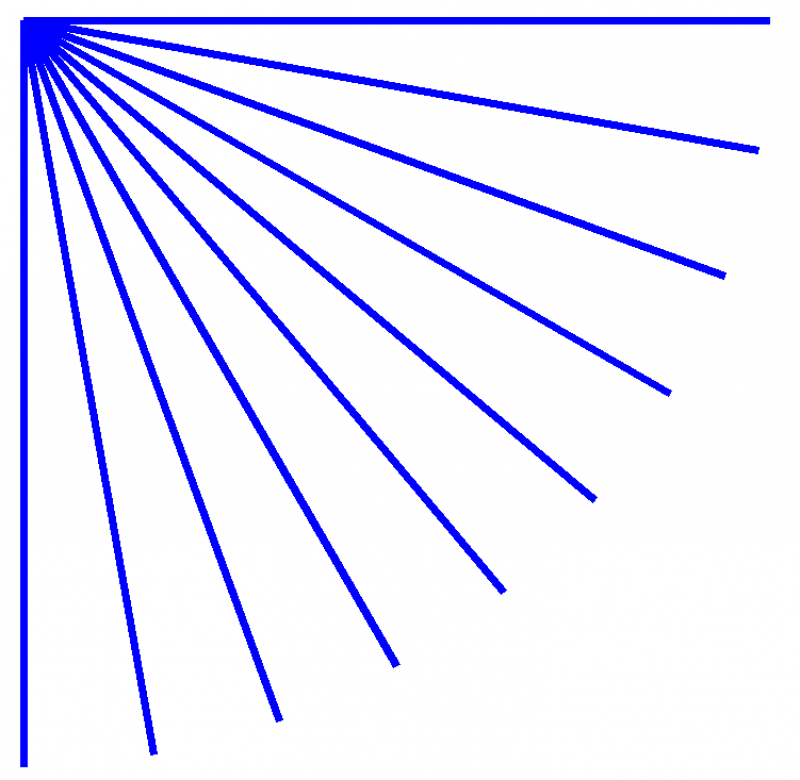

CNC bridge saw for interpolated angle cutting in all directions

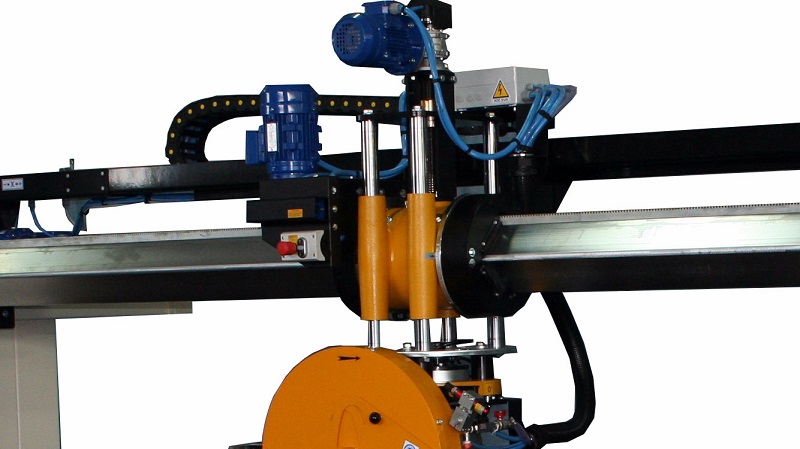

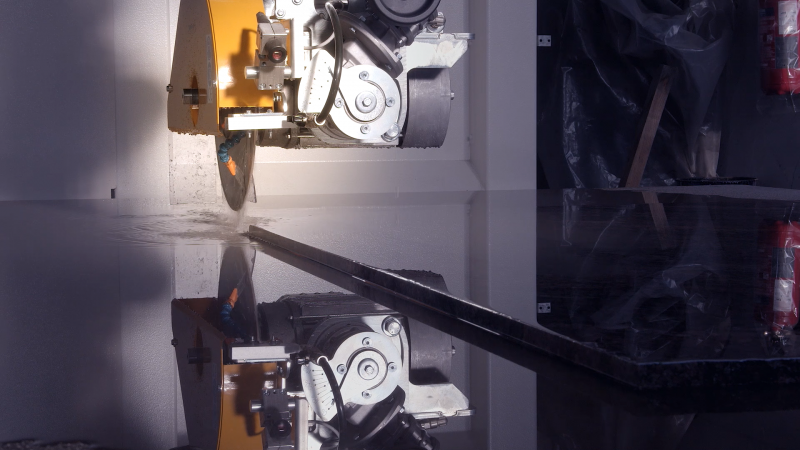

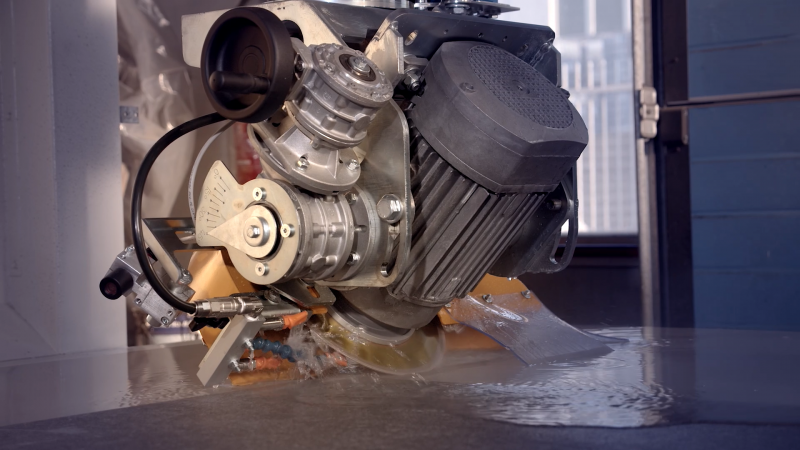

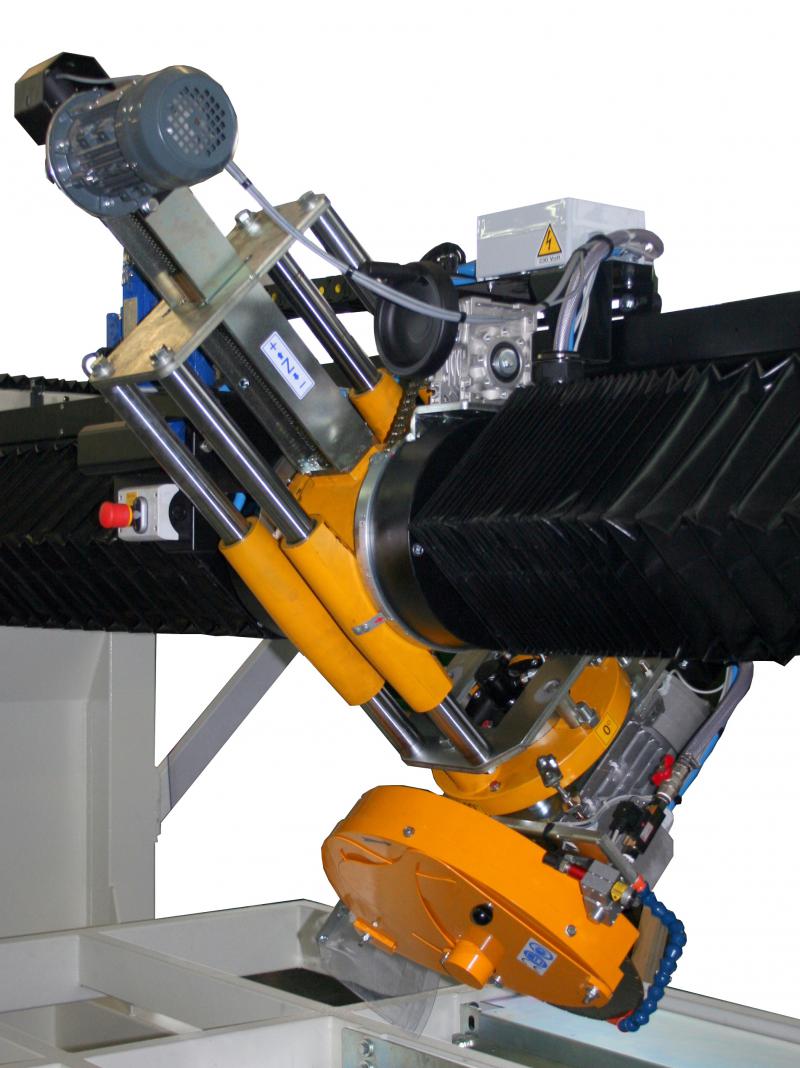

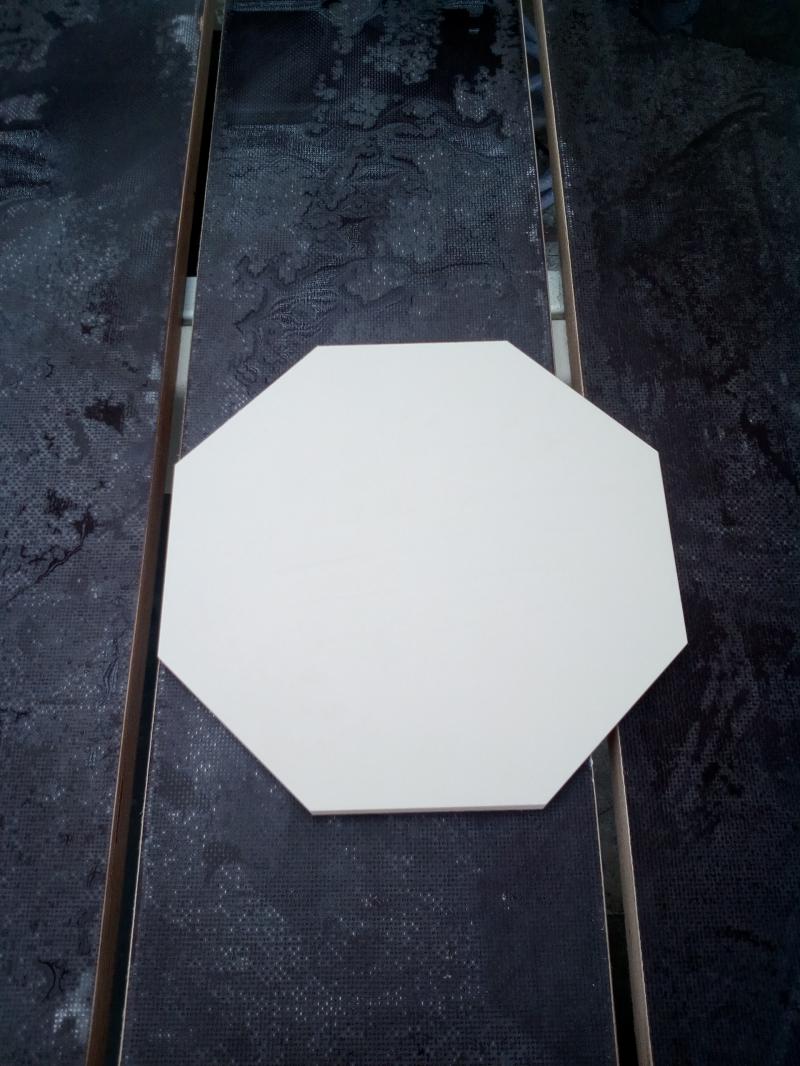

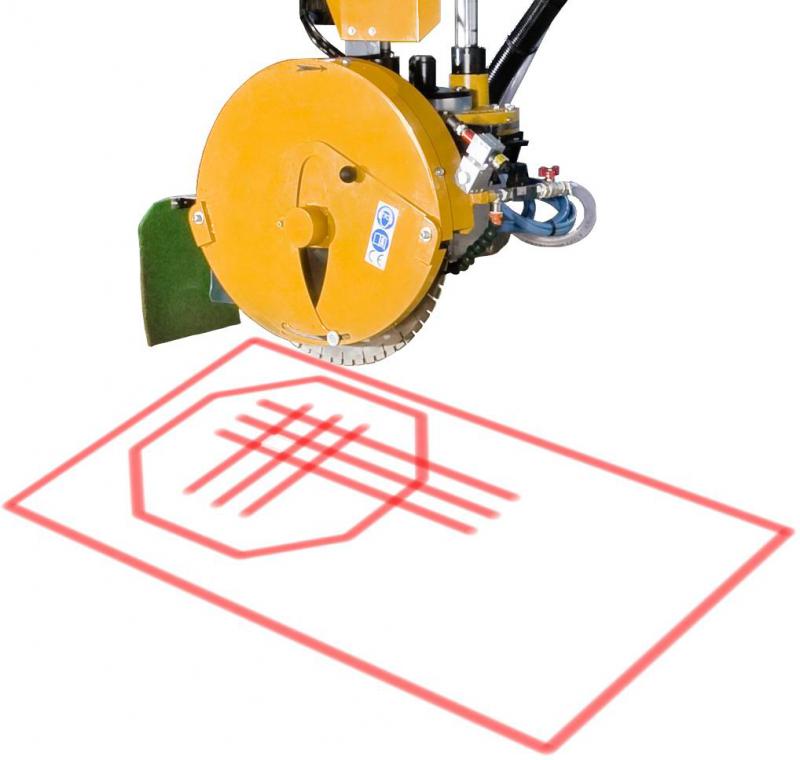

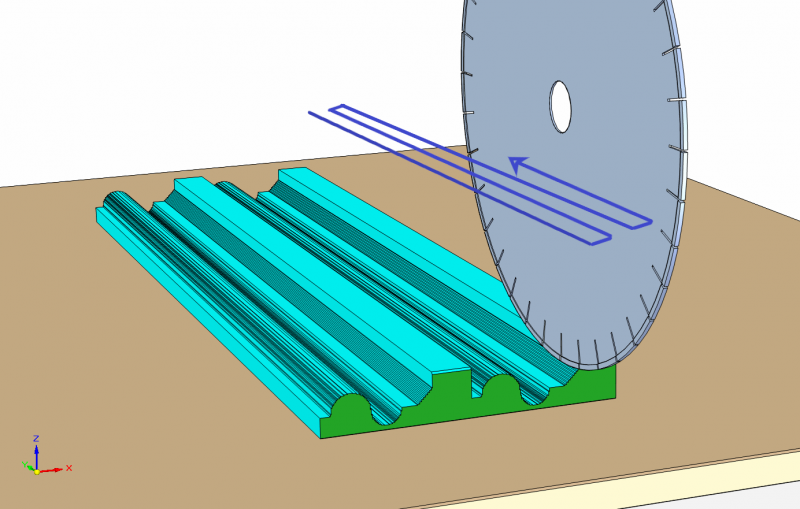

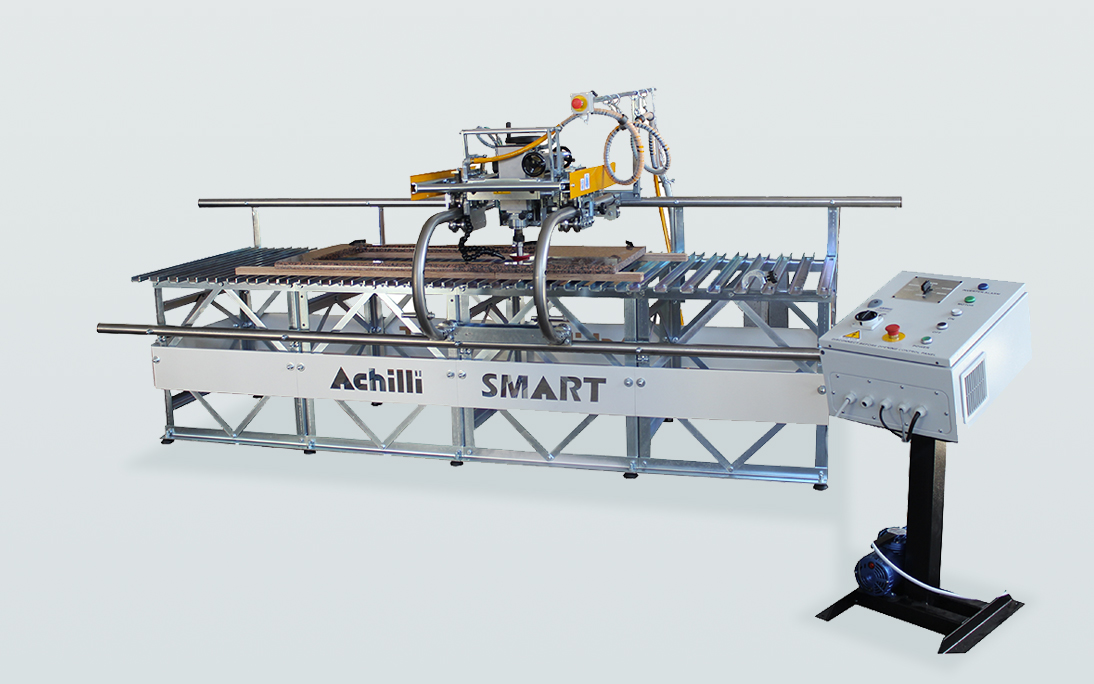

MBS TS is our best-selling bridge saw; the perfect combination of simplicity, flexibility and durability. The installation is easy and does not require foundation. The machine is equipped with a compressed, rectified and chromed “active beam” guaranteeing the utmost accuracy. The rotation of the head allows to perform interpolated angle cutting in all directions.

MBS TS is our historical monoblock bridge saw with CNC axis control unit for cuts programming:

- Customizable according to customer requirements;

- Monoblock structure for easy installation;

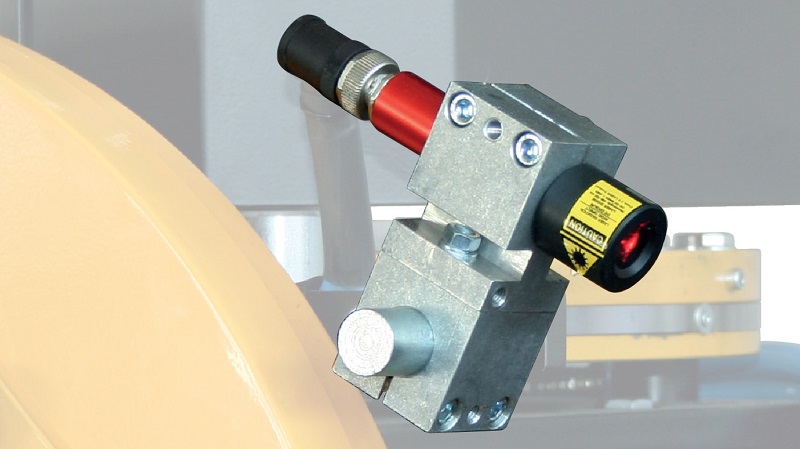

- The perfect cutting precision is guaranteed by the special design of the beam;

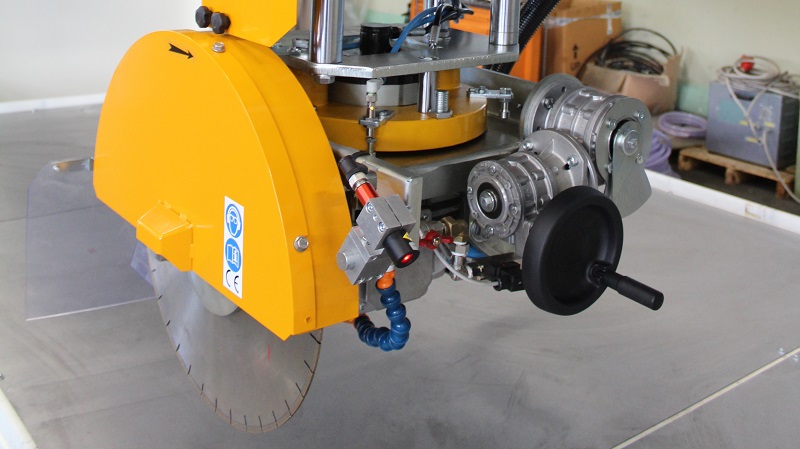

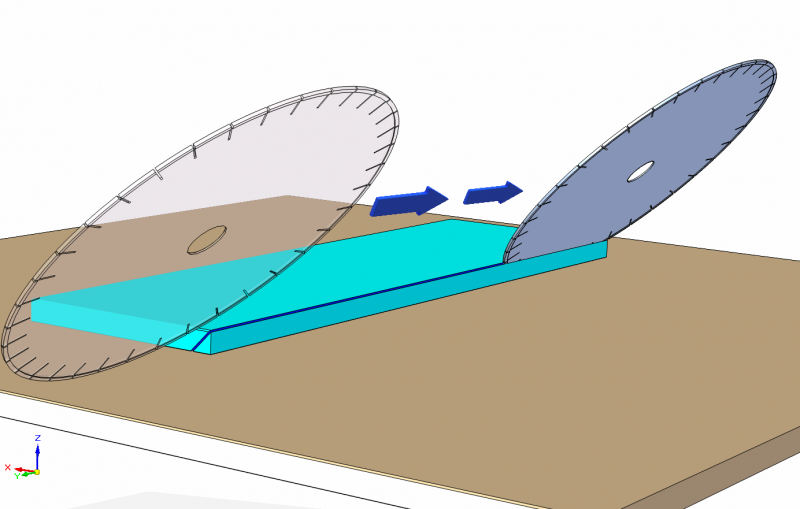

- Manual or automatic head rotation to perform interpolated angle cutting in all directions.

| X-axis travel | 3500mm (11’5”) |

|---|---|

| Y-axis travel | 1930mm (76”) |

| Z-axis travel | 350 mm (13”) |

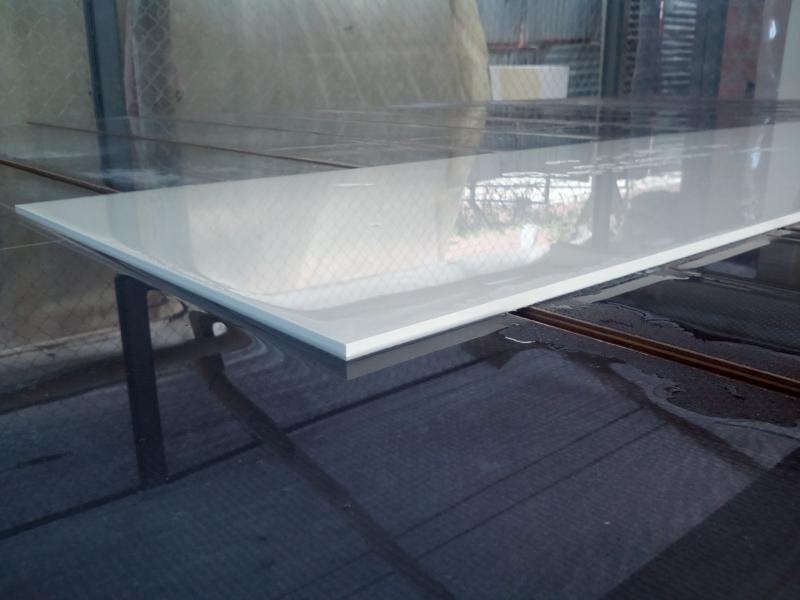

| Worktable dimensions | 4800x2200mm (15’7”x7’2”) |

| Max. diamond blade diameter | 350-525mm (14"-20") - 300-400mm (11"-15") |

| Blade bore size | 50 mm (2”) |

| Manual head tilt | 90° - 45° |

| Head rotation |

0°- 90°- 180°- 270° / 0°- 360° |

| Main motor power |

7.5kW = 10HP / 11kW = 15HP |

| Main motor rotation speed | 1400 rpm 50Hz – 1700 rpm 60Hz |

| Main motor variable speed (optional) | 800 - 3000 rpm |

| Standard voltage/frequency |

400V-50/60Hz / 230V-60Hz 3ph. |

Do you need information about Achilli products? Contact us for technical or commercial information on floor grinders, bench saws and bridge saws.

Guarantee 12 months

Qualified technical support

Training with Achilli technicians

Spare parts always available

Product: Monoblock bridge saw MBS TS