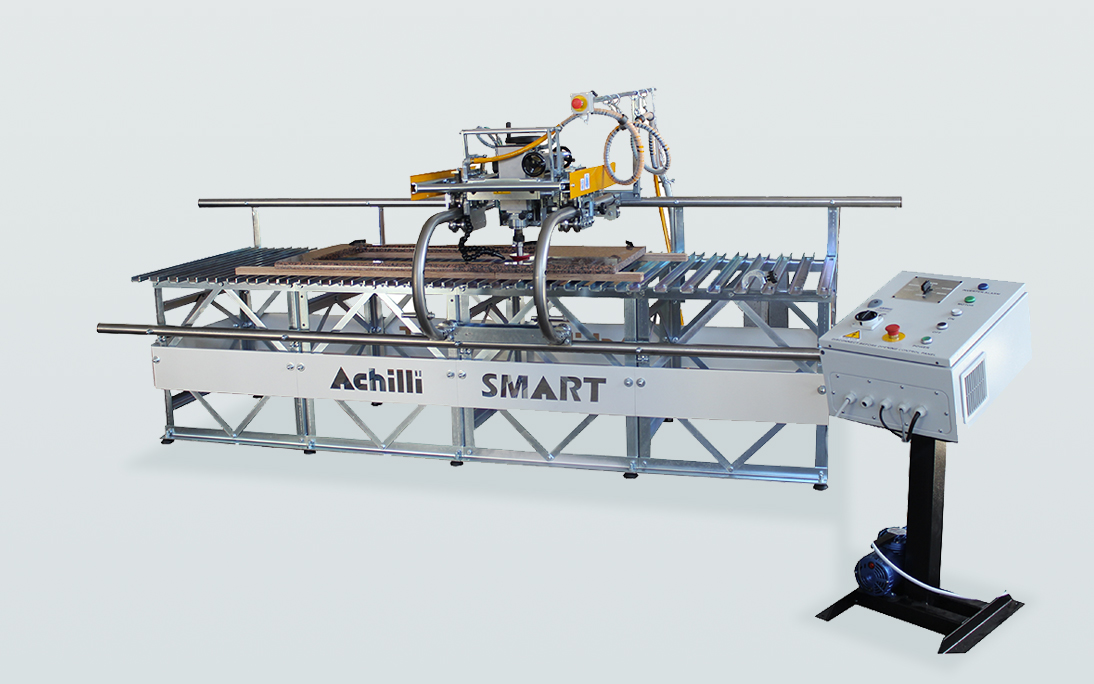

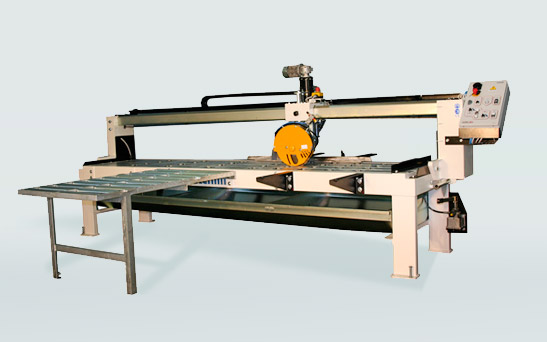

Automatic bench saw TFR A

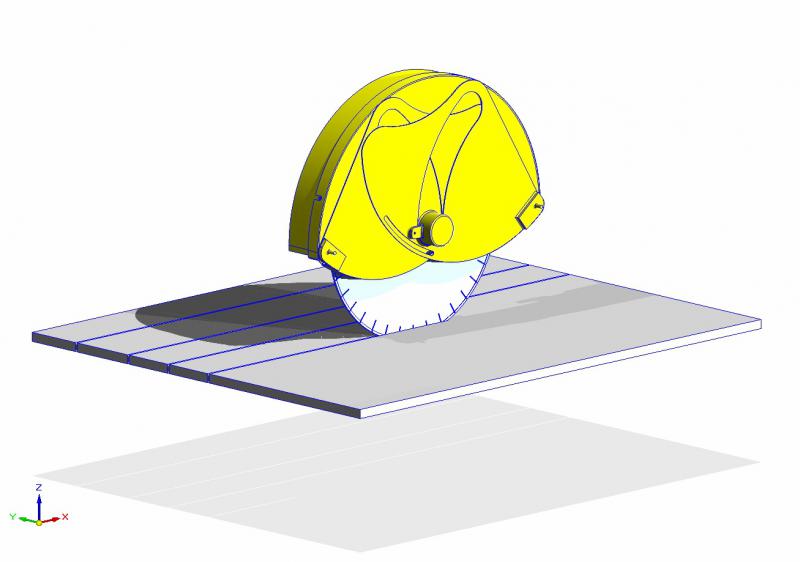

Motorized stone saw for large slabs

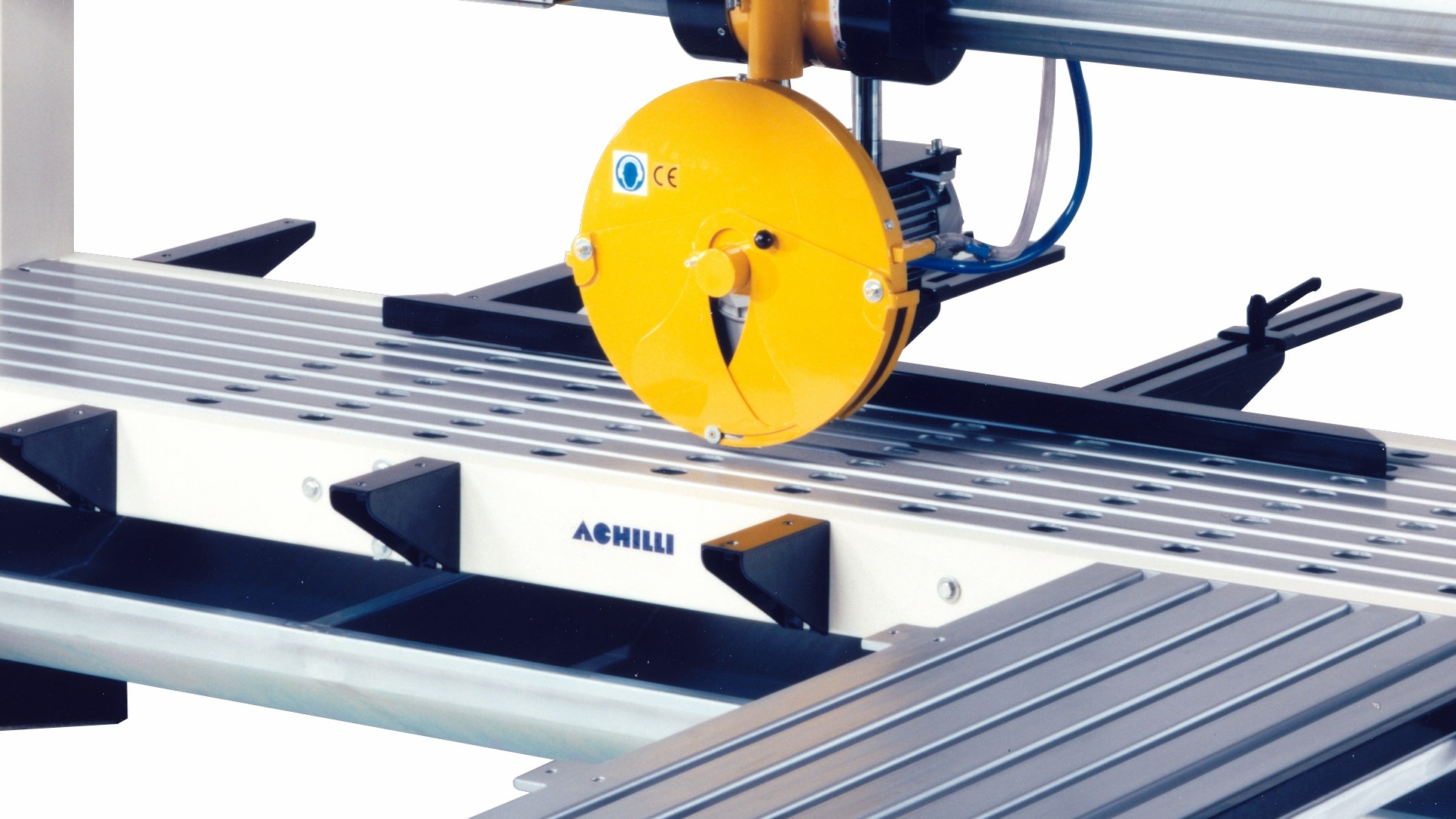

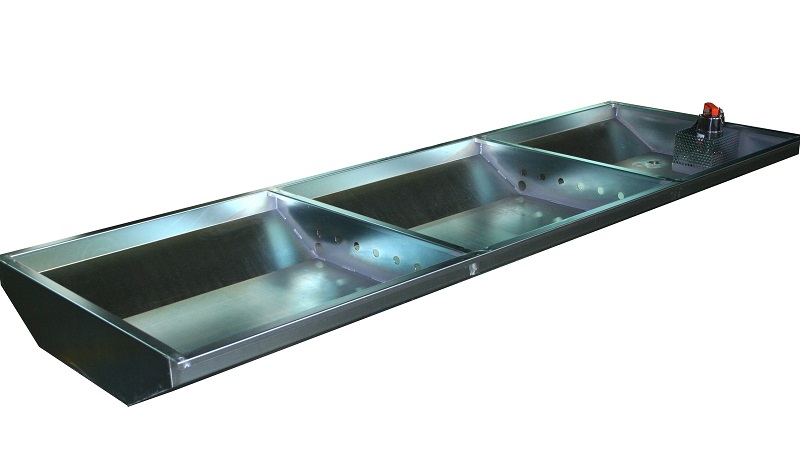

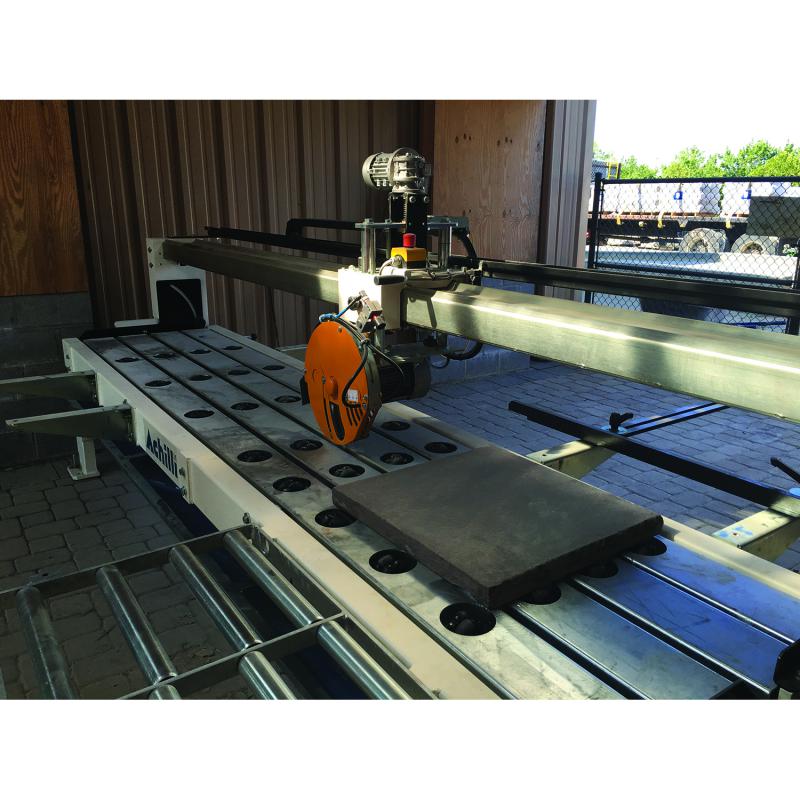

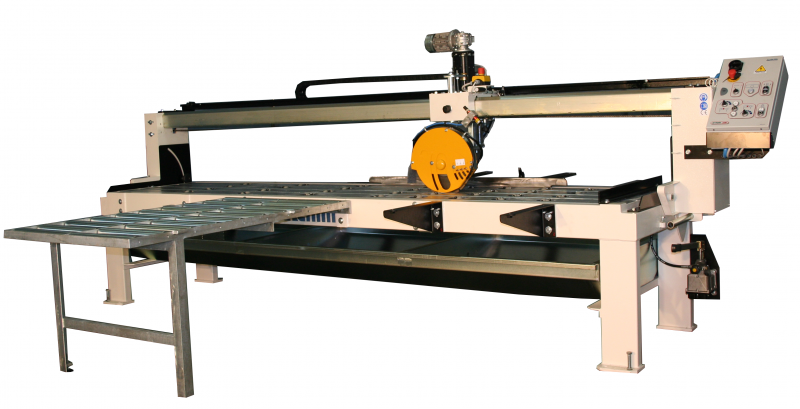

TFR-A is born from the specific needs of our customers. This motorized bridge saw combines the essentiality of a basic saw with the sturdiness of a massive frame allowing to feature pop-up rollers on the worktable for easy slab positioning.

Advantages

TFR-A is a sturdy and compact bridge saw ideal for cutting large stone slabs:

- Customizable according to customer requirements;

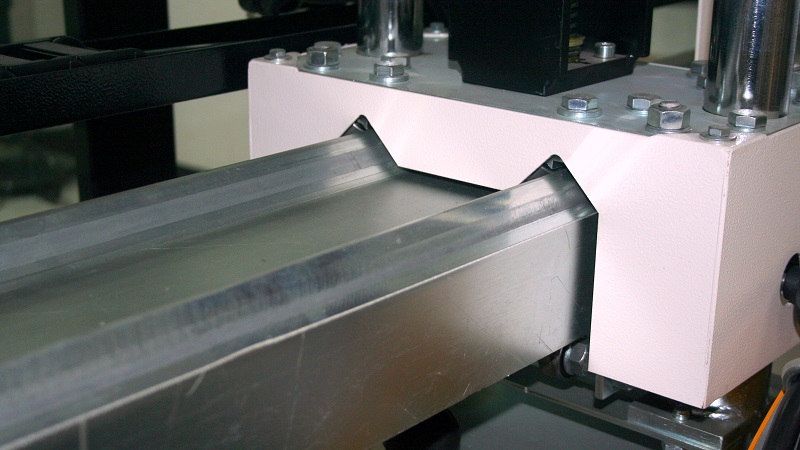

- Maximum cutting precision guaranteed by a special beam design;

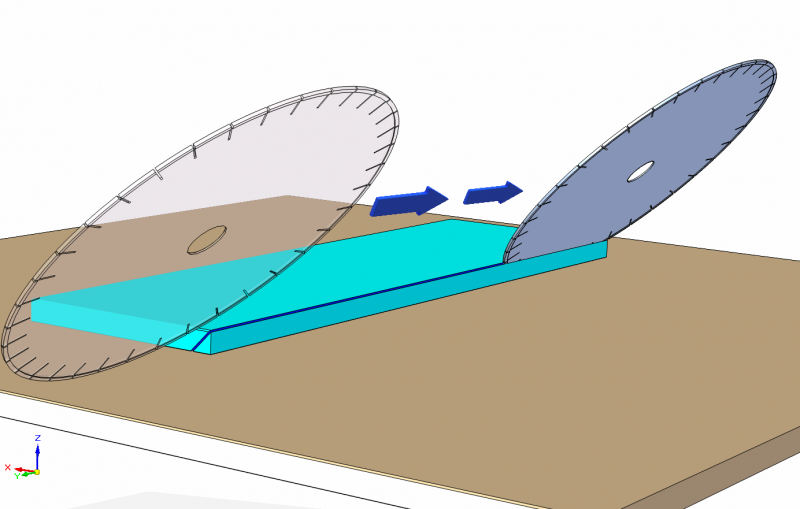

- Suitable for ceramic and sintered material slabs;

- Massive frame for processing large stone slabs;

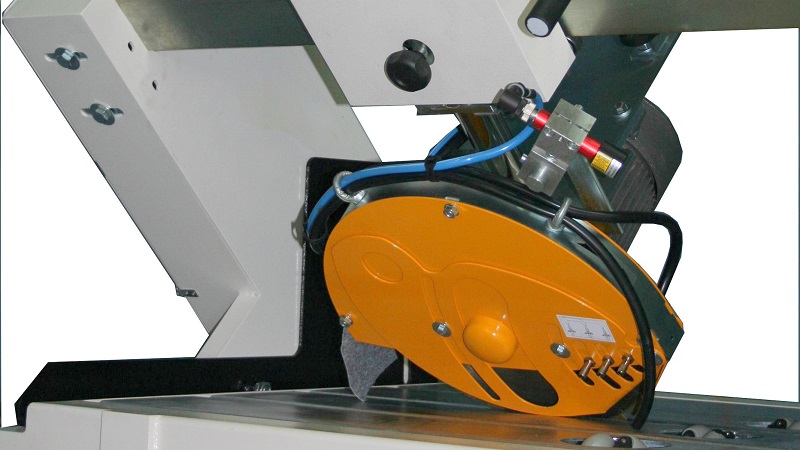

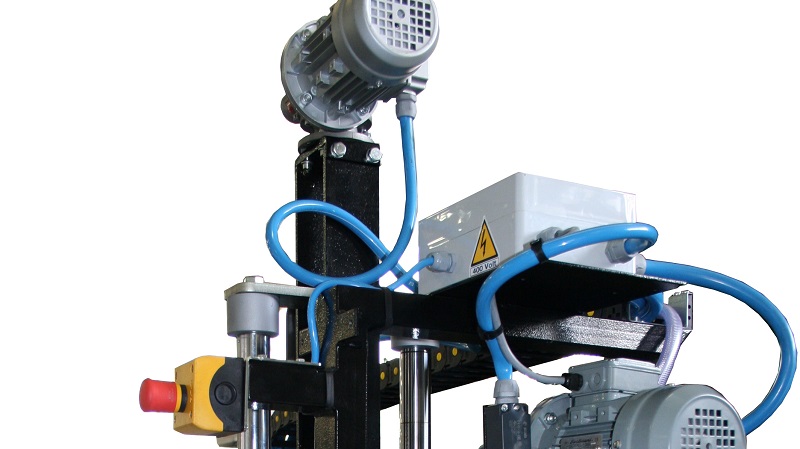

- Motorized head feed with variable speed in both directions;

- Also available with manual head feed (TFR-C).

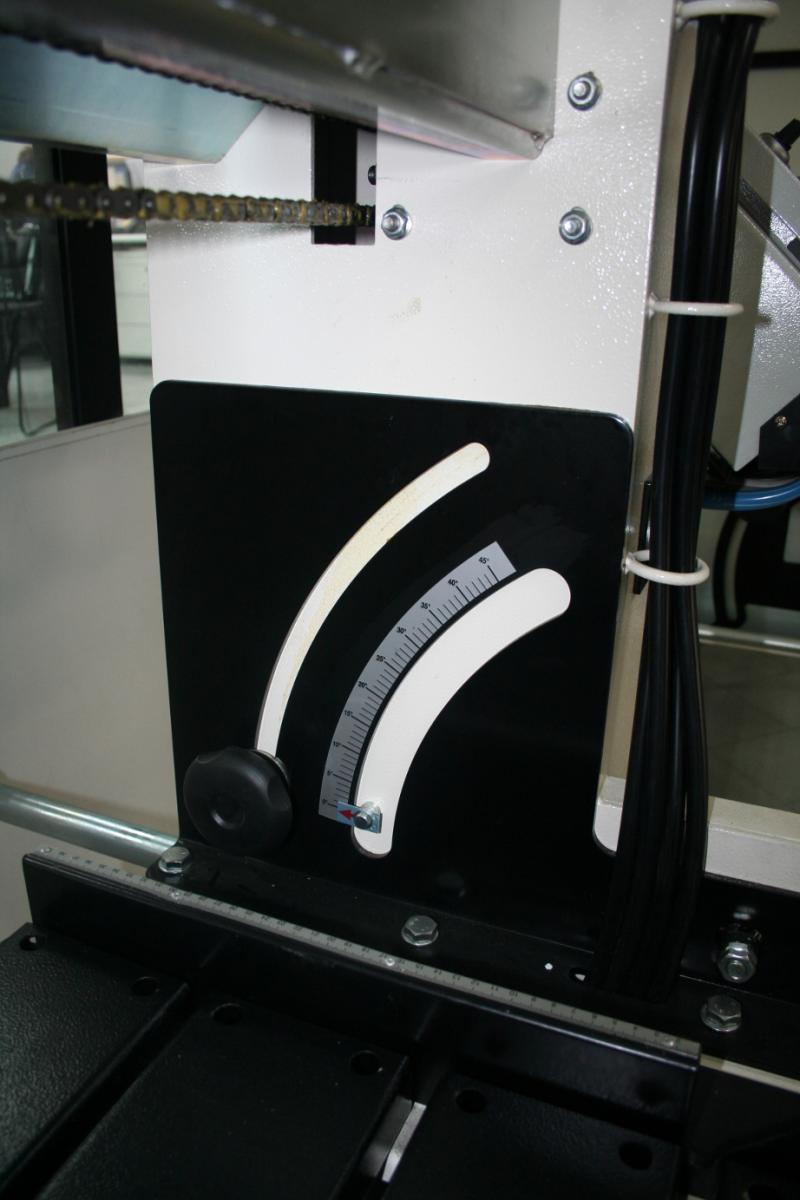

Technical details

| TFR-A | TFR-A HT | |

| Useful cut | 3300 mm (10’10”) | 3300 mm (10’10”) |

| Diamond blade diameter | 250-300-350 mm (10”–12”–14”) | 400-450-500 mm (16”–18”–20”) |

| Blade bore size | 25.4 mm (1") | 25.4 mm (1") |

| Motor power |

5kW = 7HP (3ph.) |

4kW = 5.5HP (3ph.) |

| Main motor rotation speed | 2800 rpm a 50Hz – 3400 rpm a 60Hz | 1400 rpm a 50Hz – 1700 rpm a 60Hz |

| Standard voltage/ frequency |

400V-50/60Hz /230V-60Hz 3ph. |

400V-50/60Hz /230V-60Hz 3ph. |

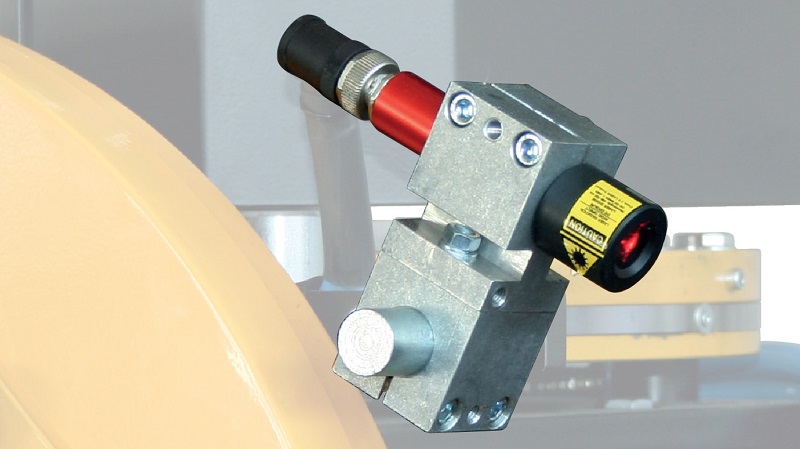

Accessories

See all products

Request Information

Do you need information about Achilli products? Contact us for technical or commercial information on floor grinders, bench saws and bridge saws.

ALWAYS BY YOUR SIDE

Guarantee 12 months

Qualified technical support

Training with Achilli technicians

Spare parts always available

Product: Automatic bench saw TFR A