Computer Numerical Control (CNC) Machines: The Complete Guide

In an increasingly innovation-driven industrial market, Computer Numerical Control (CNC) machines represent a major technological advancement with a direct impact on productivity, efficiency, and manufacturing quality.

Thanks to their high precision, flexibility, and automation, CNC machines have become indispensable across industries that require complex machining processes and large-scale production.

We have created this guide to provide all the essential information you need about computer numerical control (CNC) machines used in sheet material processing, answering the most common questions: what CNC machines are, how they work, and what advantages they offer.

What Does CNC Mean?

Let’s start with the basics. The acronym CNC stands for Computerized Numerical Control.

CNC machines are automated machine tools controlled by a computerized system that interprets numerical instructions and converts them into precise mechanical movements.

These instructions are written in a specific programming language known as G-code or ISO code, which allows full control over every aspect of the machining process—from axis movement to tool speed and feed rate—ensuring maximum accuracy and repeatability.

How Do CNC Machines Work?

The CNC machining process can be divided into several clearly defined stages:

- Design of the workpiece, created using external CAD software or directly on the machine interface.

- Program generation via CAM software, which translates the design into numerical commands.

- Machine setup, including tool selection, mounting, and calibration.

- Automatic execution of machining operations, carried out by the machine according to the programmed instructions.

CNC machines operate in a closed-loop system, constantly monitoring position and movement through encoders, motors, and drives. This continuous feedback allows machining accuracy down to one-hundredth of a millimeter, making CNC technology extremely reliable and efficient.

CNC Machines and CNC Machining Centers: What Are They and How Are They Used?

The main difference between a CNC machine and a CNC machining center lies in their production capacity and operational complexity.

CNC machines include a wide range of automated tools where the operator sets the program and the machine performs the machining operations autonomously, with minimal human intervention limited to loading, unloading, and supervision.

A CNC machining center, on the other hand, is a highly versatile and multifunctional machine capable of automatically carrying out multiple operations such as milling, drilling, and turning, all within a single setup.

Thanks to numerical programming, CNC machining centers guarantee high productivity, precision in series production, and the ability to perform complex machining tasks, making them ideal for larger production volumes.

Automatic CNC Saws: Features and Functions

Automatic CNC saws, especially those designed for processing materials such as marble, granite, and ceramic, represent the technological evolution of traditional cutting machines.

The most advanced models are bridge saws with a monoblock structure, equipped with a rotating head, interpolated movements, and dedicated CNC software.

Key features of automatic CNC saws include:

- Complete control of head movement

- Automatic cycle programming

- Multi-axis movements for complex machining operations using different tools

- High standards of safety, productivity, and cutting precision

Automatic CNC saws are ideal for complex and repetitive machining operations, helping to reduce human error while significantly improving the quality of the finished product. Their precision makes them perfect for architectural projects, custom furnishings, and artistic stone processing.

Achilli CNC Milling Machines: GOLD and MBS TS

GOLD and MBS TS are the flagship CNC milling machines produced by Achilli. Both models are designed to deliver maximum efficiency, reliability, and extremely high machining precision, while meeting different production requirements.

Let’s take a closer look at their main characteristics.

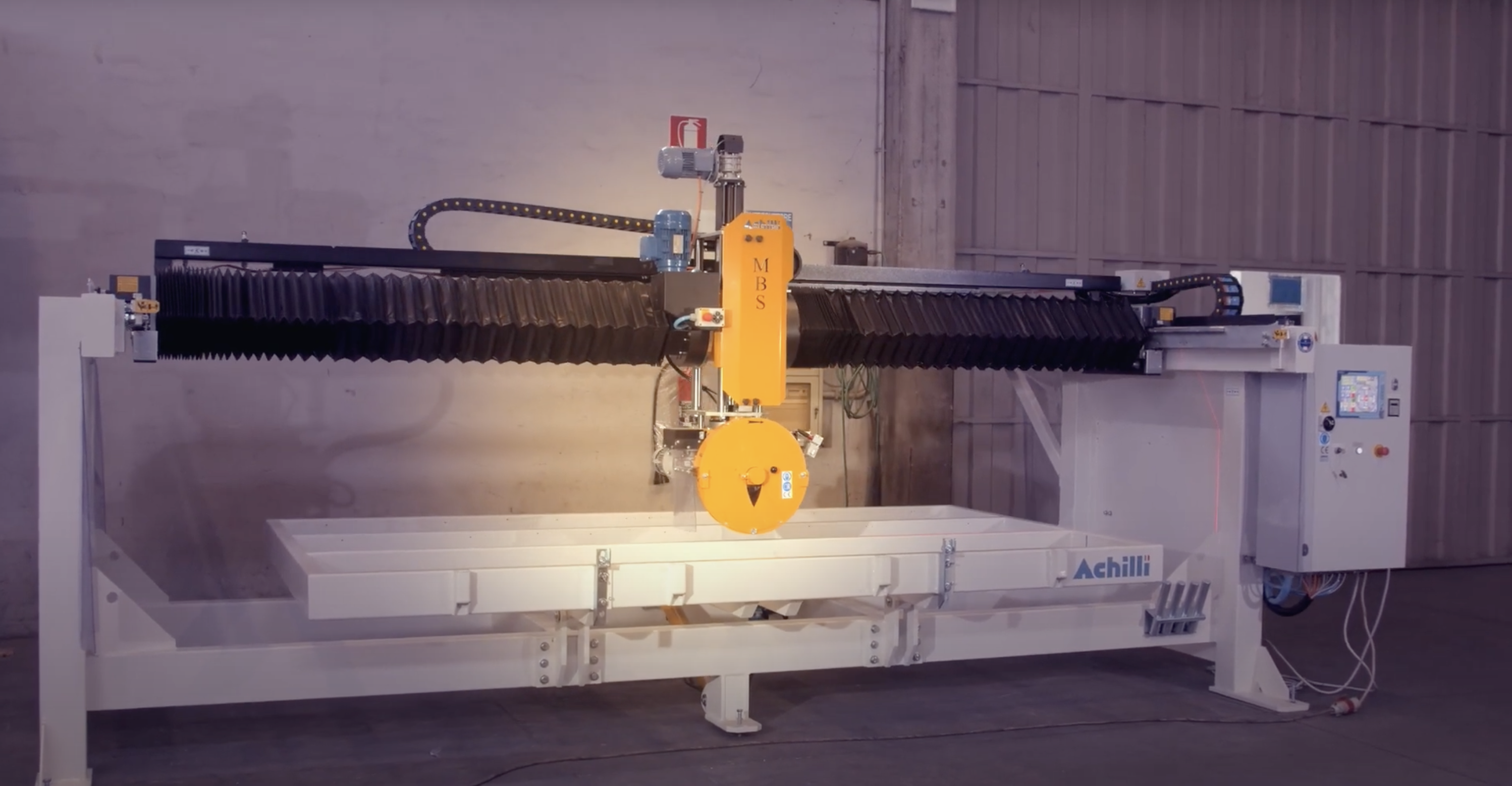

MBS TS: CNC Monoblock Bridge Saw

The MBS TS is a compact CNC monoblock bridge saw, engineered for stability, ease of use, and versatility.

Its monoblock structure allows installation without the need for foundations, ensuring fast setup and operational readiness.

Main features include:

- Rotating head

- Interpolated movements for cuts in all directions

- Intuitive touchscreen control interface

- Preset programs for specific cuts, geometric shapes, surface planing, and inclined planes

- Multiple configurable options, including tilting table, roller conveyor, protective bellows, and water collection tray

The MBS TS is the ideal solution for artisan workshops and small to medium-sized businesses looking for a high-performance yet user-friendly CNC machine.

GOLD: 4- or 5-Axis CNC Milling Machine for Industrial Production

The GOLD series is designed for companies that demand maximum precision, advanced automation, and industrial-level performance.

Key features of the GOLD CNC milling machines include:

- Movement on 4 or 5 interpolated axes

- Brushless motors with recirculating ball linear guides on X, Y, and Z axes

- Compatibility with multiple tools, including diamond blades, incremental cutters, and drills

- Fixed or hydraulically tilting worktable

- User-friendly software with customizable macros

With the GOLD CNC milling machine, it is possible to carry out cutting and drilling cycles, complex shaping, decorative profiling, recessing, and incremental milling, achieving an excellent surface finish and outstanding precision.

How to Choose the Right CNC Machine

Purchasing a CNC machine is a strategic investment, and choosing the right model is essential to maximize its benefits. Here are some key factors to consider:

- Define your production goals: production volume, material type, and machining complexity directly influence the choice of CNC machine.

- Evaluate your available infrastructure: workspace dimensions, power supply, facilities, and slab loading systems. In limited spaces, a compact and versatile CNC machine may be the best solution.

- Select the appropriate level of automation, whether you need a simple automatic machine or a fully integrated solution for complex, high-volume production.

If you would like to learn more about the technical features of Achilli CNC machines or receive expert advice on choosing the most suitable CNC milling machine for your business, contact us today.