Cutting Marble: An Essential Guide to Sawing Machines and Rotation Speeds

Marble, known for its timeless charm and exceptional durability, stands as one of the most commonly used materials in both furniture and architecture. Whether it's for flooring or vertical surfaces, marble is a pivotal material, adding a touch of elegance to any space. Yet, the art of cutting marble and shaping it to meet specific requirements demands precision and the right machinery.

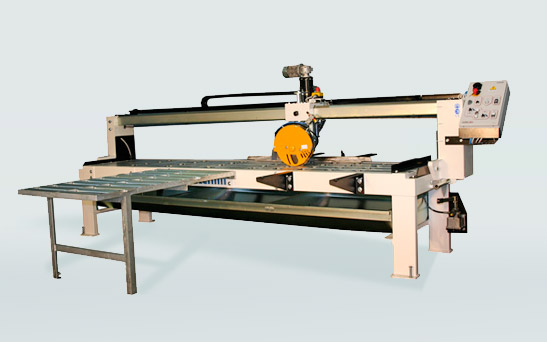

Bridge saws are highly efficient machines, ideally suited for cutting marble, but not all models are created equal. It is therefore essential to understand how to cut marble and what are the parameters for choosing the right sawing machine

The Versatility of Marble in Furnishings and Flooring

Marble is renowned for its beauty and its ability to bring elegance to any environment. It is frequently used in flooring, wall coverings, kitchen countertops, and decorative elements. Its natural luster, unique grain, and remarkable durability make it the perfect choice for crafting luxurious and sophisticated designs.

However, the merits of marble extend beyond aesthetics and style. Marble is also valued for its enduring hardness and resistance, though it is a delicate material to work with. These very characteristics make the process of cutting marble more intricate. Therefore, it is crucial to employ the right machinery for the job. Let's delve into the main parameters to consider when choosing a saw for cutting marble.

Selecting the Right Saw for Cutting Marble

There are two primary methods of cutting marble:

- Wet Cutting: In this method, machines are equipped with a diamond disc that cuts the marble while being continuously cooled by a jet of water. This cooling process prevents the disc from overheating and minimizes dust production.

- Dry Cutting: Dry cutting saws employ specific diamond discs to cut without the use of water.

For professional marble cutting, the preference should be for a wet cutting saw. Given marble's exceptional hardness, a cooling system is essential to prevent the diamond blade from overheating during cutting. Using water allows for smoother cutting, prevents overheating of the blade, and minimizes dust.

However, selecting the ideal saw for cutting marble involves more than merely opting for a wet cutting saw. Several essential parameters need to be taken into account.

Here's a summary of the critical characteristics to consider when choosing a saw for cutting marble:

- Blade Cooling: Adequate cooling of the diamond blade is crucial, and water saws provide continuous cooling with a recirculation pump that sprays water precisely where the material contacts the blade. A protective flow switch ensures the flow of water during cutting to prevent damage to the disc due to dry operation.

- Diamond Disc: Choosing the right diamond blade is of utmost importance, as it must be suited to the thickness and material of the slab to be cut. Thicker materials require larger-diameter cutting discs. Therefore, it's essential to select a cutting machine that accommodates discs with the appropriate diameter for the slabs you typically work with.

- Main Motor Rotation Speed: This is perhaps the most critical factor to consider, directly influenced by the material and disc diameter. For professional settings handling various materials, a saw equipped with an inverter is the best choice, as it allows you to adjust the speed according to the material being cut. When cutting marble, the peripheral speed of the disc should typically range from 40-50 meters per second. Keep in mind that the peripheral speed varies depending on the disc diameter used. If your cutting machine lacks an inverter, you can find the right peripheral speed by altering the diameter of the discs used.

In the table below, we provide some data on recommended disc diameters and rotation speeds for cutting marble while maintaining a peripheral speed of 40-50 m/s. Typically, a motor runs at 1400 rpm or 2800 rpm at 50 Hz and 1700 rpm or 3400 rpm at 60 Hz.

|

Blade diameter |

Rotation speed |

|

250 mm (10”) |

3100 – 3700 rpm |

|

300 mm (12”) |

2600 – 3200 rpm |

|

350 mm (14”) |

2200 – 2700 rpm |

|

400 mm (16”) |

1900 – 2400 rpm |

|

450 mm (18”) |

1700 – 2100 rpm |

|

500 mm (20”) |

1500 – 1900 rpm |

|

600 mm (24”) |

1300 – 1600 rpm |

|

625 mm (26”) |

1200 – 1500 rpm |

For example, if you have a 2800 rpm motor and need to cut a marble slab with a machine that accepts 250-300-350 mm diameter discs, the ideal choice would be a 300 mm disc.

Cutting marble is a process that demands precision and expertise. Using the right saws is essential to achieve flawless cuts, just as it is crucial to select the appropriate disc diameter and rotation speed based on the type of marble and the slab's thickness.

If you're in search of an efficient solution for cutting marble, please visit our website's stone cutting machines section.